Problems that solves

Shortage of inhouse software developers

Shortage of inhouse IT resources

High costs of IT personnel

Shortage of inhouse IT engineers

Values

Reduce Costs

Enhance Staff Productivity

About Product

Description

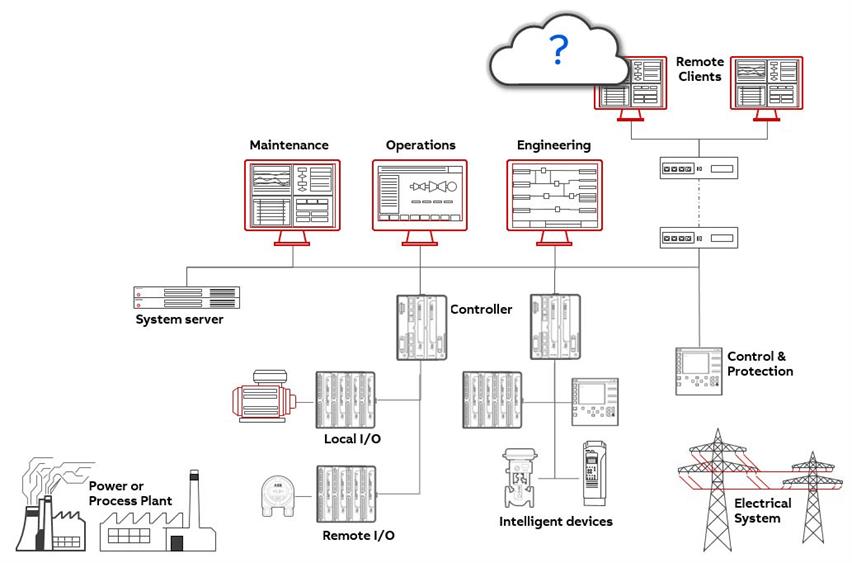

ABB AbilityTM is our unified, cross-industry digital capability — extending from device to edge to cloud — with devices, systems, solutions, services and a platform that enable our customers to know more, do more, do better, together.

Sense

The Symphony Plus control system is the benchmark technology to control complex technical systems, sensing, collecting and presenting information.

Analyze

The people that are responsible for operating the plant are themselves part of a closed loop system. They look at the collected data that is presented on the operator screen, and analyze it (through knowledge and experience) - also in collaboration with ABB experts - to take the necessary actions to run the plant in the desired state.

Act

Maintenance and plant operations can be regarded as closed loop systems. The diagnostic data collected from the equipment and the automatic or human interpretation of the data are both used to determine equipment service or operational changes.

ABB AbilityTM Symphony Plus brings a multitude of advantages over an open loop system

- Disturbances in the process can be addressed, the data shows if the outcome does not match the intended target. With the proper control variable in place, the process can meet the target despite the disturbance.

- Changes in the process can be handled with ease. The actions based on the data can address a change and still achieve the intended results.

- By increasing the frequency of the collected data, deviations are observed faster, and can be dealt with more quickly.

- While off-line, data collection deviations may be observed in the lab or after a quarterly inspection. Continuous data collection may trigger immediate resolution at a higher rate and therefore avoid major deviations.

- Control loops can be tuned and optimized.

- Analytics parameters can be adjusted to match a changed environment.

- Changes observed in off-site cloud based analytics could lead to an optimization of the on-site control loops (e.g. in the control system), leading to an overall optimized system across the layers of the stack.

Scheme of work